Production Systems

- TOP

- Production Systems

From prototype development to mass production

We meet the needs of customers by applying our accumulated experience and advanced methods. We manufacture all of our own products, from creating the mold designs to the production and use of high-precision molds. We use our own high-level, controlled mass production systems.

Metal molds

Design

Manufacture

Press working

Prototype production

Mass production

Degreasing and deburring

Cleaning&barrel polishing

Inspection

Dimensions,

shape&appearance

shape&appearance

Storage

Warehouse

Major Equipment List (in Japan)

| Production equipment | Progressive Press machine, 5~160t | 147 units |

| Transfer Press machine, 7~160t | 106 units | |

| Hydrocarbon Washing machine | 10 units | |

| Methylene chloride Washing machine | 2 units | |

| Hot air vacuum Drying machine | 2 units | |

| Barrel Polishing machine | 2 units |

| Inspection equipment | Coordinate measuring machine | 2 units |

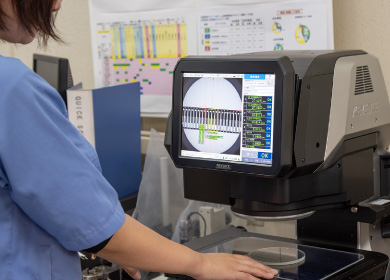

| Vision measuring system | 6 units | |

| Surface roughness and contour measuring machine | 3 units | |

| Contour measuring machine | 3 units | |

| Surface roughness measuring machine | 1 unit | |

| Roundness measuring machine | 1 unit | |

| Profile projector | 2 units | |

| Vickers hardness tester | 1 unit |

| Machine tools | Vertical machining center | 1 units |

| Surface grinder | 4 units | |

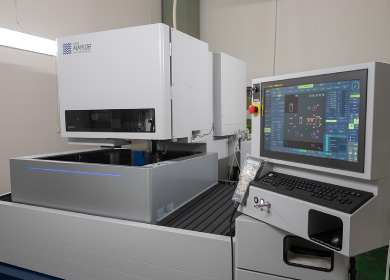

| Wire-cut electric discharge machine | 3 units | |

| Die-sinker electric discharge machine | 4 unit | |

| Small-hole drilling electric discharge machine | 1 units | |

| Profile grinder | 5 units | |

| Cylindrical grinding machine | 2 units | |

| Internal grinding machine | 4 units |

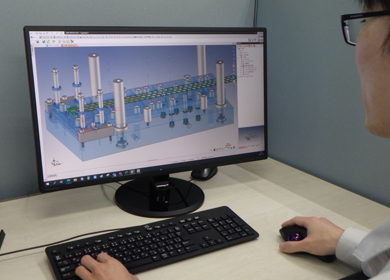

| Design | CAD (3D) | 3 units |

| CAD (2D) | 12 units | |

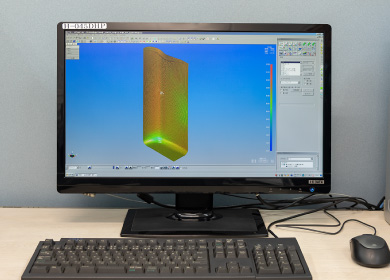

| CAE Press forming simulation | 1 unit |